Nickel is an often alloyed element, since it is able to alloy to almost any metal, and as a result, nickel tubing is predominantly fabricated from nickel alloys. Read More…

We will meet your nickel alloy needs with bar, strip or wire forms. Our ISO 9001-registered company would like to be your nickel supplier for nickel alloys — copper nickel, nickel copper, nickel chromium, nickel manganese, soft magnetic nickel iron. Round up to 15"; flat roll thin as .0002".

As a manufacturer of stainless steel and nickel alloy products, Best Stainless & Alloys offers stainless steel and nickel alloy bar, plate, and pipe. We are a leader in the distribution of pump shaft quality material. Other services that we offer are grinding, forging, castings, plasma cutting, heat treating and boring.

Cobalt and nickel alloys are manufactured here. Through our many service centers, we can supply you with nickel plate, nickel bar, forging stock, fittings, flanges, tubing and wire. When your application is in a severely corrosive or high-temperature atmosphere, we are the nickel supplier for you.

Since 1952, the Welding Warehouse has been manufacturing and distributing a variety of stainless steel products as well as titanium, aluminum, nickel, low alloy steel, magnesium, silver alloy and copper base alloy products. We also offer precision wire processing. In addition, we meet aerospace material specifications.

More Nickel Tubing Suppliers

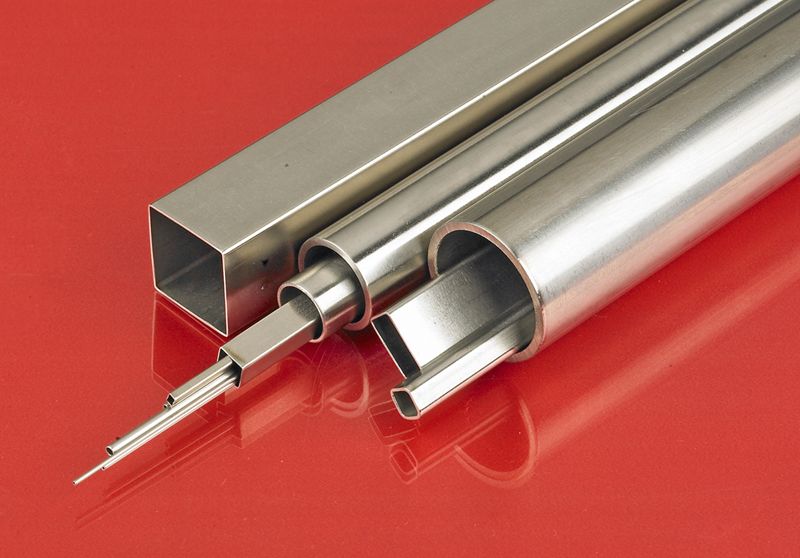

Some common nickel alloys used for tubing include nickel-chromium alloys (Nichrome), nickel-titanium alloys (Nitinol), nickel superalloys (Inconel), and nickel-copper alloys (Monel). Due to the wide range of nickel alloys, nickel tubing can offer a variety of characteristics that appeal to diverse industries including: residential, for use in plumbing, refrigerators and air conditioning systems; medical, for applications requiring hypodermic tubing; automotive, for internal systems tubing such as vehicle brake tubing; industrial manufacturing, for use in material handling and processing applications as well as equipment such as heat exchangers and furnaces; and petrochemical for oil and gas extraction and processing.

An attractive and durable metal, some additional characteristics of nickel include malleability, ductility, sanitary, and excellent strength and toughness in extreme environments.

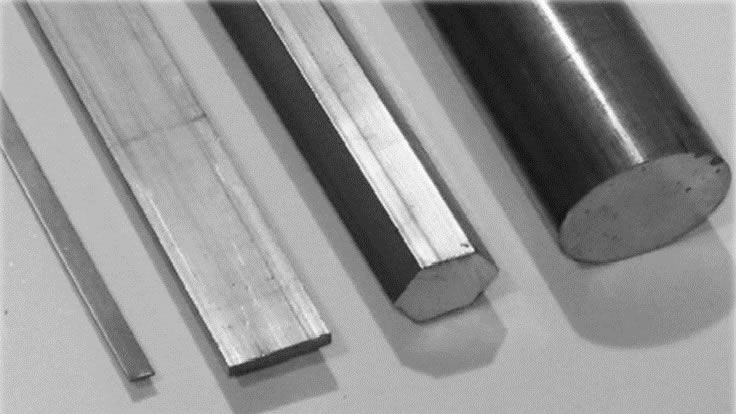

Nickel tubing can refer to tubing that is wholly fabricated from nickel alloys, or it can refer to tubing that has been fabricated from a different material and then nickel coated. When the tube is completely fabricated from nickel alloys, the two most common processes of tube fabrication are tube rolling and tube extrusion. In tube rolling, pre-impregnated nickel alloys are cut and rolled around a mandrel.

Next, the nickel is wrapped around the mandrel in order to eliminate any retained air and lastly, the nickel is heat-cured and will form a hollow tube once the mandrel is removed. In tube extrusion, a round nickel billet is pressed through a die, which is a hollow profile that shapes the nickel into a hollow tube-shape by means of a pin attached to the die as the billet is squeezed through.

For tubing that is nickel-coated rather than wholly nickel, electroplating is the most common. In electroplating, an electric current is used to reduce positively-charged ions of nickel from a solution and thus, coat the metal tubing with a layer of nickel. Electroless nickel plating may also be used, in which a catalytic process is used to reduce the nickel ions from a solution, which results in the coating of the tube with nickel without having to use electrical energy.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services