Nickel metal is a lustrous, silvery-white, gold-tinged metallic element found in nature. It is a classified as a transition metal. Nickel has five stable isotopes, an atomic weight of 58.71, an atomic number of 28, and the symbol Ni. It has a boiling point of 2730 °C, a melting point of 1455 °C, and is solid at room temperature. It is ductile, hard, ferromagnetic, and resistant to rust and corrosion. Nickel metal is mined from the earth. Read More…

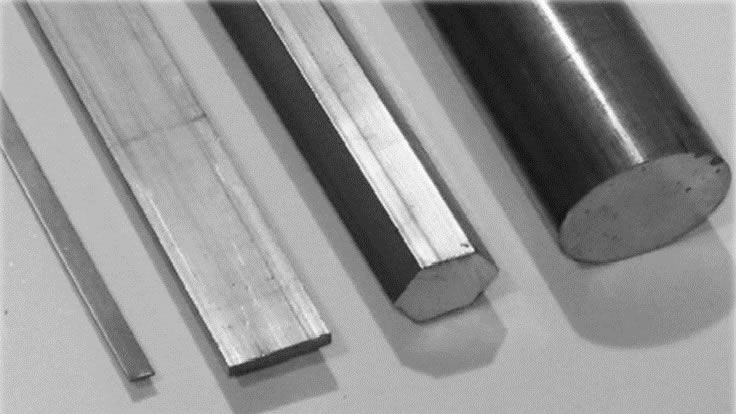

We will meet your nickel alloy needs with bar, strip or wire forms. Our ISO 9001-registered company would like to be your nickel supplier for nickel alloys — copper nickel, nickel copper, nickel chromium, nickel manganese, soft magnetic nickel iron. Round up to 15"; flat roll thin as .0002".

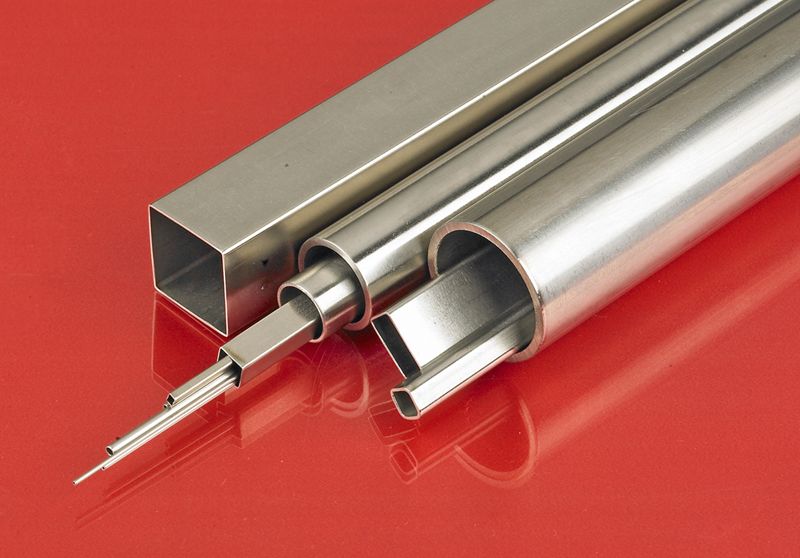

As a manufacturer of stainless steel and nickel alloy products, Best Stainless & Alloys offers stainless steel and nickel alloy bar, plate, and pipe. We are a leader in the distribution of pump shaft quality material. Other services that we offer are grinding, forging, castings, plasma cutting, heat treating and boring.

Cobalt and nickel alloys are manufactured here. Through our many service centers, we can supply you with nickel plate, nickel bar, forging stock, fittings, flanges, tubing and wire. When your application is in a severely corrosive or high-temperature atmosphere, we are the nickel supplier for you.

Since 1952, the Welding Warehouse has been manufacturing and distributing a variety of stainless steel products as well as titanium, aluminum, nickel, low alloy steel, magnesium, silver alloy and copper base alloy products. We also offer precision wire processing. In addition, we meet aerospace material specifications.

More Nickel Metal Suppliers

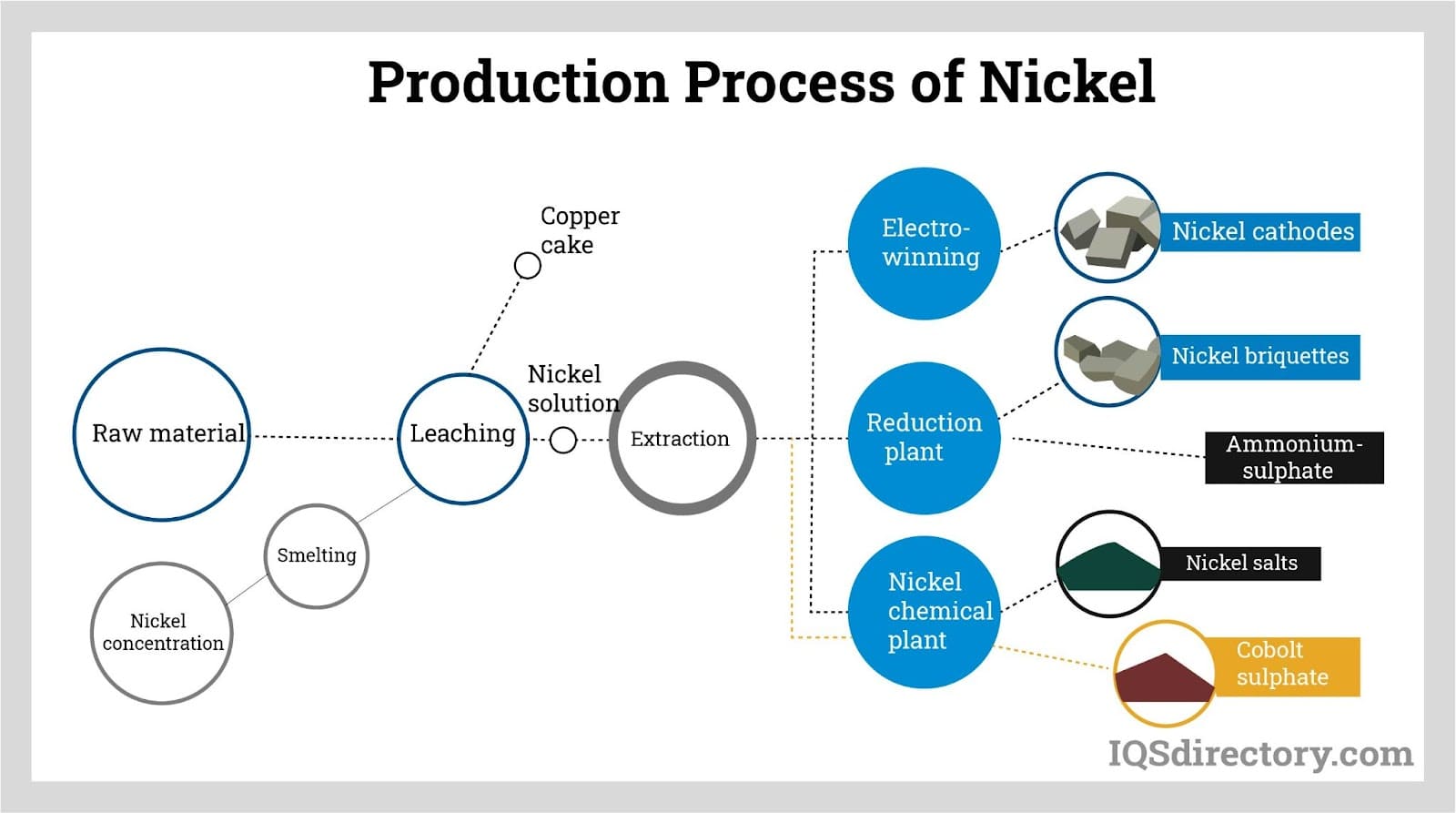

How Nickel Metal Is Produced

An ore is a naturally occurring rock that is found deep inside the earth's crust and contains one or more valuable minerals that can be extracted, purified, and sold to generate revenue. Typically, metals are present in the ore. Nickel's two primary ore types are magmatic sulfide and laterites.

Nickel is mined and extracted from the ores in different ways. The process used to extract the laterite ore is known as open-cut mining. It requires massive amounts of energy during the drying process. Water must be removed from the chemically bonded laterite ores because they contain large volumes of moisture and hydroxides.

Sulfide ores are extracted using underground mining methods. These involve casting, molding, separating, and shaping. Through methods like nickel extrusion, cold drawing, and electroless nickel plating, nickel can be machined into various shapes.

Nickel Extraction and Processing

Extractive metallurgy is a method used to separate the raw metal from its ore. Pyrometallurgical extraction, which uses high temperatures to promote chemical reactions, is the most popular method. Open-cut mining techniques are often used to acquire laterite ore. Open-cut mining extracts ore from an open-air pit. Laterite ore is often mined with machinery like front-end loaders, draglines, and large shovels.

Extraction of Nickel from Sulfide Ores

Sulfide ore is typically mined underground. After sulfide ores are mined, crushed, and processed, the selective flotation method extracts nickel from the trash. In the selective flotation procedure, ore is combined with chemicals to create air bubbles. As the air bubbles ascend through the mixture, naturally light sulfide particles will stick to the bubbles’ surfaces. They are gathered, and six to twelve percent of them are nickel.

Magnetic separators help when some of the nickel-containing sulfides are magnetic in nature. Magnetic separators are occasionally used alongside or instead of the flotation process. Before being discarded, the waste materials frequently go through another cleansing process. A second selective flotation process must be carried out since certain sulfide ores have almost equal quantities of copper and nickel; this produces a separate nickel concentrate and low nickel copper concentrate.

Extraction of Nickel from Laterite Ores

The nickel from laterite ores is sulfur-free. They do, however, contain a lot of water in the form of moisture and hydroxides. The drying and smelting process uses energy from other sources since lateritic ores cannot achieve the same reaction temperatures as those of sulfide ores. The drying procedure is used to get the ore's moisture out. The procedure is completed in a large kiln furnace.

The drying procedure yields nickel oxide, which is reduced to get nickel metal. For the smelting process, electric furnaces with a 45–50 megavolt–ampere rating are often employed. These furnaces may operate between 1360°C and 1610°C.

Types of Nickel Metal

Due to its favorable properties, Nickel is frequently alloyed with other elements. Chromium, cobalt, copper, and iron are some examples of alloying components.

Brushed Nickel

Brushed nickel is nickel that has been polished by a wire brush or other rough surface. This gives the nickel faint, patterned lines, with a shiny finish. Although brushed nickel is resistant to corrosion, it tarnishes quickly. It may get a milky white patina as it ages and is exposed to the elements. Nevertheless, this is readily resolved by wiping the brushed nickel with a mild cleanser or a mixture of water and white vinegar. Doorknobs and kitchen faucets can be made of brushed nickel.

Cupro Nickel

Cupro nickel is an alloy made of nickel, copper, iron, and manganese. This alloy's copper composition ranges from 60 to 90 percent, making copper the primary element. The alloy is silver in hue. It is extremely ductile, has good thermal conductivity, and has high resistance to corrosion caused by seawater. It also has good tensile strength. Pipelines, heat exchangers, and desalination facilities all use cupro-nickel.

Nickel 200

Nickel 200 is wrought nickel, with a purity of around 99.6%. It has traces of sulfur, carbon, silicon, copper, manganese, iron, and manganese. Pipelines and rocket engines both use nickel 200.

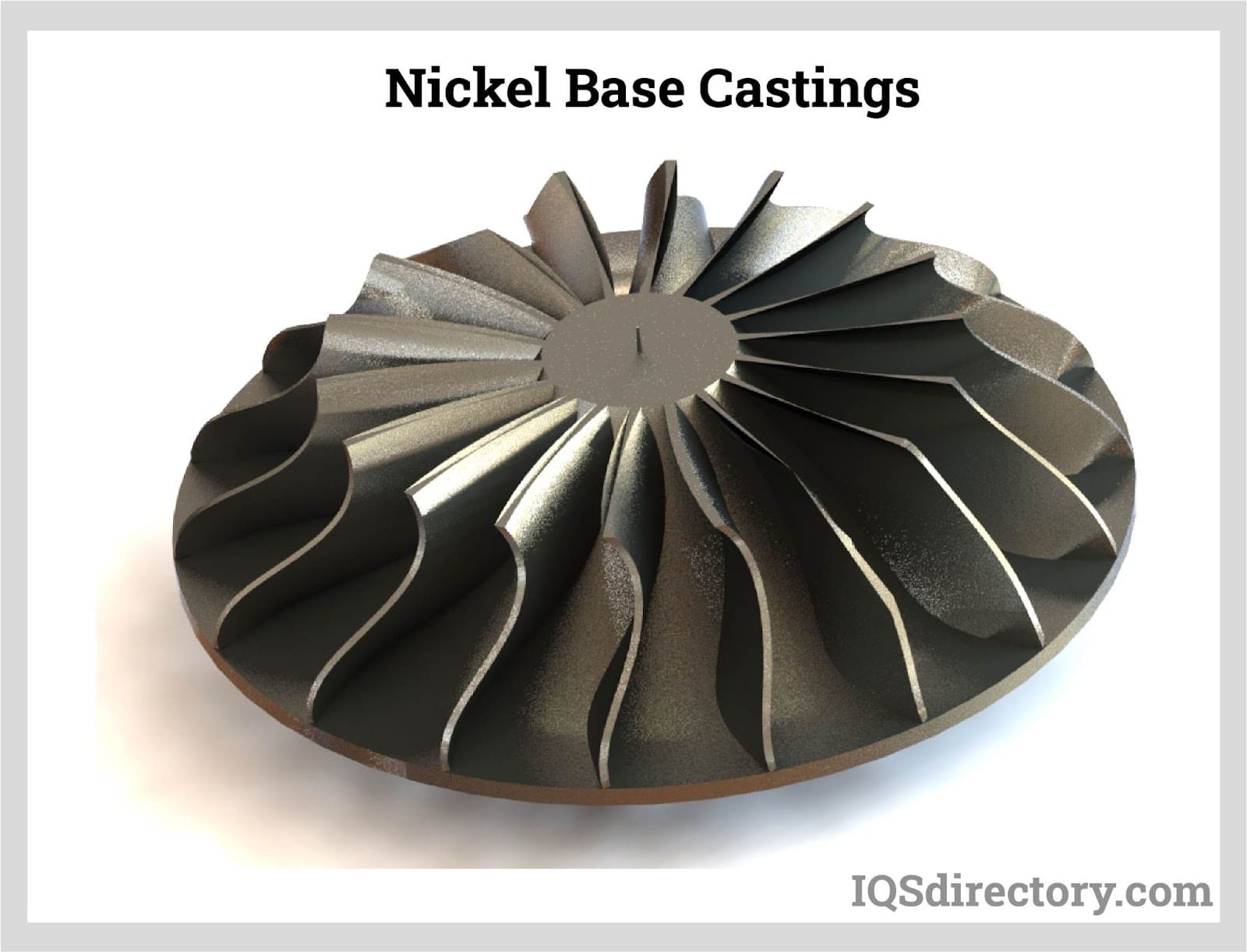

Casting Alloys

Casting alloys are created by melting the alloy and then pouring it into a mold. This can be molded more easily than other alloys. Casting alloys are known for their great strength and are heat, corrosion, and wear resistant.

Nichrome Alloy

Nichrome is a nickel-chromium alloy with high electrical and temperature resistance. It is silvery-gray in hue. Its primary applications include resistance wire, dental restorations, and heating elements for appliances like toaster ovens and space heaters. Additionally, nichrome alloy serves as a bridge wire in electric ignition systems like electric matches and model rocket igniters. It is also used in motorcycle exhaust systems, flame testing, and ceramics.

Applications and Uses of Nickel Metal

As an alloying metal, nickel has several vital uses. Iron, copper, and chromium are a few metals that it can mix with. The aviation, marine, chemical, and energy industries all use nickel alloys. The electroplating industry uses nickel as a metal. This is done for both ornamental purposes and to stop or slow down the corrosion of other metals.

Nickel alloys help create rechargeable battery systems, which are crucial for transportation, power tools, and emergency power supplies. Several significant chemical processes, including the hydrogenation of vegetable oils, the reforming of hydrocarbons, and the creation of fertilizers, insecticides, and fungicides, all benefit from the catalytic properties of nickel.

Choosing the Correct Nickel Metal Supplier

To ensure you have the most productive outcome when purchasing nickel metal from a nickel metal supplier, it is important to compare several companies using our directory of nickel metal suppliers. Each nickel metal supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each nickel metal business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple nickel metal companies with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services