Nickel plate is commonly used as a corrosion inhibitor for the manufacture of computers, cellphones, and electronic devices. It also can provide solderability, hardness, wearability, friction loss, paint adhesion, conductivity, and shielding. Read More…

We will meet your nickel alloy needs with bar, strip or wire forms. Our ISO 9001-registered company would like to be your nickel supplier for nickel alloys — copper nickel, nickel copper, nickel chromium, nickel manganese, soft magnetic nickel iron. Round up to 15"; flat roll thin as .0002".

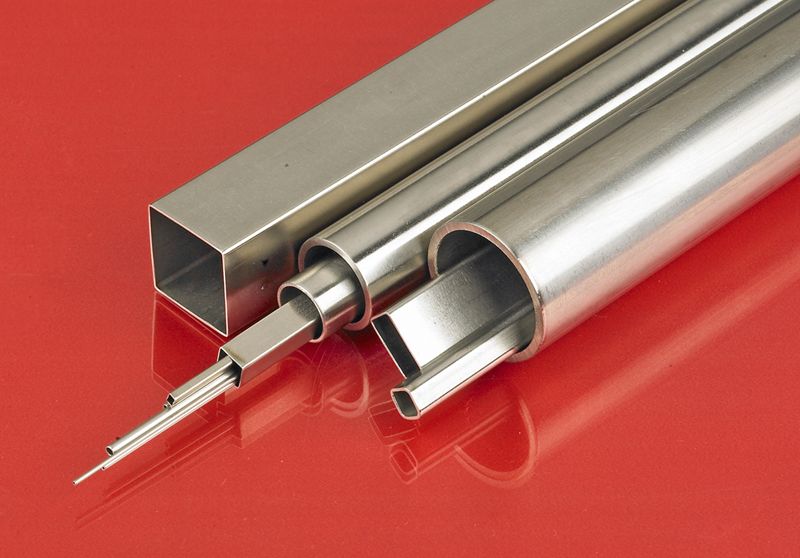

As a manufacturer of stainless steel and nickel alloy products, Best Stainless & Alloys offers stainless steel and nickel alloy bar, plate, and pipe. We are a leader in the distribution of pump shaft quality material. Other services that we offer are grinding, forging, castings, plasma cutting, heat treating and boring.

Cobalt and nickel alloys are manufactured here. Through our many service centers, we can supply you with nickel plate, nickel bar, forging stock, fittings, flanges, tubing and wire. When your application is in a severely corrosive or high-temperature atmosphere, we are the nickel supplier for you.

Since 1952, the Welding Warehouse has been manufacturing and distributing a variety of stainless steel products as well as titanium, aluminum, nickel, low alloy steel, magnesium, silver alloy and copper base alloy products. We also offer precision wire processing. In addition, we meet aerospace material specifications.

More Nickel Plate Suppliers

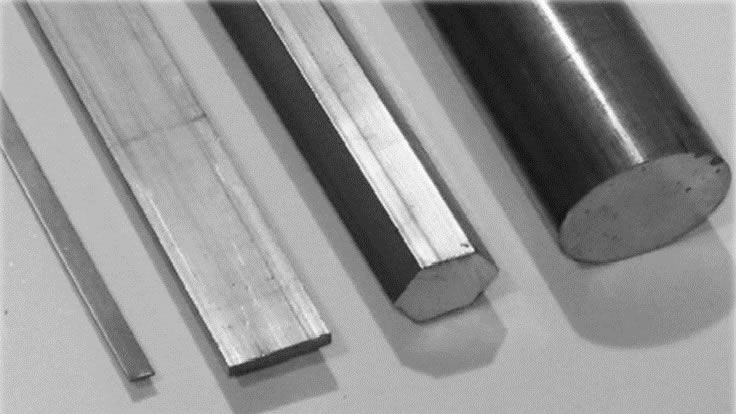

Nickel plate refers to thick, flat stock metal shapes that exhibit uniform thickness and are formed using billets or ingots of pure nickel or any of a number of nickel alloys. In general, manufacturers consider planes with a thickness between 0.25 inches and 0.5 inches to be plates, while thinner measurements would be nickel sheets or foils. The categories made by individual nickel suppliers may vary with regards to the acceptable range of thicknesses.

The nickel plates themselves may or may not be used as the finished product, though they and the many products made from them are extremely versatile and widely employed across the industrial sector. Power generation, chemical processing, building and construction, marine, material handling, electronics, aerospace, automotive, medical and numerous other industries find many applications for metal plates in stock and finished form.

In some instances, the plates are fused to substrates through a process known as electroless nickel plating to form a protective surface. This and general uses for nickel plate take advantage of the materials natural ductility, malleability, hardness, ferromagnetism, electrical and heat conductivity as well as corrosion resistance. As these features vary among the many nickel alloys, it is important to consider the specific composition of a nickel plate prior to purchase.

Before the production of nickel plate can begin, this naturally occurring element must be mined from the earth, most often by means of pyrometallurgical extraction or hydruometallurgy. The resulting nickel ore is then refined until the desired purity is reached. Commercial grade nickel products are composed of 99.6% nickel and minimal amounts of other elements while some nickel alloys contain as little as 32.5% nickel.

Once the desired composition is achieved, stock billets, ingots, bars or other pre-forms are transformed into plates. Though casting and extrusion may be used, roll forming is the most common method employed in the manufacture of nickel plate. Hot rolling requires that the material be heated, with optimal working temperatures for nickel between1,800°F and 2,200°F, while cold rolling maintains room temperature.

Hot or cold, the material is fed through a pair of rollers that compress the metal into a thin sheet. In some cases several rollers or multiple passes through the same rollers is necessary to achieve the desired thickness. The thickness, which should be uniform throughout the plate, as well as gauge, length, and width, should be carefully considered with regard for the intended use of the plate as should processing techniques which may impact the characteristics and qualities of the nickel or alloy.

Finished plates may be used as such for supports or plating purposes or may undergo a range of secondary processes such as stamping, punching, cutting, bending, or other until the final component is produced.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services