Nickel is an incredibly common alloying element since it is both highly versatile and able to alloy with almost any metal. As a whole, nickel-based alloys offer heat-resistance as well as high corrosion-resistance against a broad spectrum of corrosive media such as chemical, alkalis, petroleum and seawater. Read More…

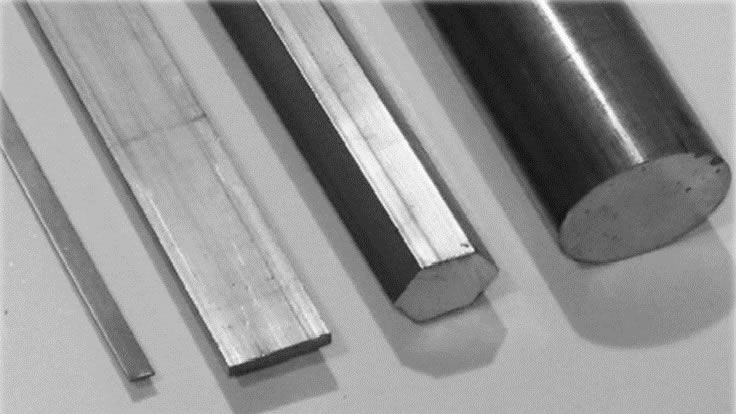

We will meet your nickel alloy needs with bar, strip or wire forms. Our ISO 9001-registered company would like to be your nickel supplier for nickel alloys — copper nickel, nickel copper, nickel chromium, nickel manganese, soft magnetic nickel iron. Round up to 15"; flat roll thin as .0002".

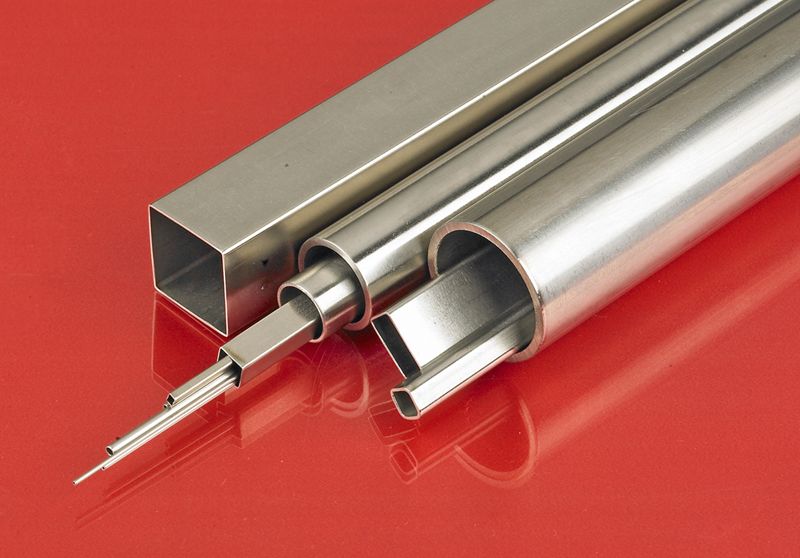

As a manufacturer of stainless steel and nickel alloy products, Best Stainless & Alloys offers stainless steel and nickel alloy bar, plate, and pipe. We are a leader in the distribution of pump shaft quality material. Other services that we offer are grinding, forging, castings, plasma cutting, heat treating and boring.

Cobalt and nickel alloys are manufactured here. Through our many service centers, we can supply you with nickel plate, nickel bar, forging stock, fittings, flanges, tubing and wire. When your application is in a severely corrosive or high-temperature atmosphere, we are the nickel supplier for you.

Since 1952, the Welding Warehouse has been manufacturing and distributing a variety of stainless steel products as well as titanium, aluminum, nickel, low alloy steel, magnesium, silver alloy and copper base alloy products. We also offer precision wire processing. In addition, we meet aerospace material specifications.

More Nickel Alloy Suppliers

Some common elements that nickel is alloyed with to form nickel alloys included iron, copper, chromium, manganese, carbon and silicon. As a result of the wide range of elements that nickel is able to alloy to, there is a correspondingly vast number of industries that nickel alloys are utilized in including: medical, used in eye-glass frames, hypodermic tubing, surgical sutures and more; power generation, for use in steam turbine power plants, nuclear power plants and varied other applications; military, used in weapons, vehicles and identification tags; industrial manufacturing, for use in corrosive material handling and various machinery such as direct current (dc) motors or generators; marine, for shipping vessels, off-shore oil rigs and small parts such as springs or fasteners; and aerospace, for use in gas turbines, jet engines and components such as piping and shims.

There are a vast number of nickel alloys, which are often categorized in terms of their second most prominent element, the characteristics they display, or the uses they are being put to. For instance, a nickel alloy with the composition of 55% nickel and 45% titanium is referred to as Nitinol, also called a nickel-titanium alloy, or a shape memory alloy.

Another example is a nickel alloy with a composition of 80% nickel and 20% chromium, called Nichrome, also called a nickel-chromium alloy, or an electrical resistance alloy. Some other popular types of nickel alloys include Hastelloy, Cupronickel, Monel, Inconel, German silver and Alumel.

The many nickel alloys are typically broken down into four main types in regards to their characteristics: low-expansion alloys, which include nickel alloys that are specifically engineered to have low thermal expansion; electrical resistance alloys, which are nickel alloys with a high nickel content; soft magnetic alloys, which are nickel alloys with high magnetic permeability and low saturation induction; and shape memory alloys, which are nickel alloys that are capable of returning to their prior shape upon undergoing the appropriate heating schedule.

Electrical resistance alloys include two sub-categories: resistance alloys and heating alloys, which contain silicone and possibly niobium in addition to nickel and chromium.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services