Any of the nickel-copper alloys in the Monel family, which was initially produced in 1905, comprise around 66 percent nickel and 31.5 percent copper, along with trace quantities of silicon, iron, manganese, and carbon. Monel alloys, which are stronger than pure nickel, resist corrosion caused by various causes, including quickly moving seawater. They are used in producing wires, sheets, tubes, rods, bolts, plates, nuts, nails, rivets, screws, valves, tube fittings, fasteners, etc., and are easily created through hot- and cold-working, machining, and welding. The alloy is frequently found as Monel 400, 405, and K-500, among others. Read More…

We will meet your nickel alloy needs with bar, strip or wire forms. Our ISO 9001-registered company would like to be your nickel supplier for nickel alloys — copper nickel, nickel copper, nickel chromium, nickel manganese, soft magnetic nickel iron. Round up to 15"; flat roll thin as .0002".

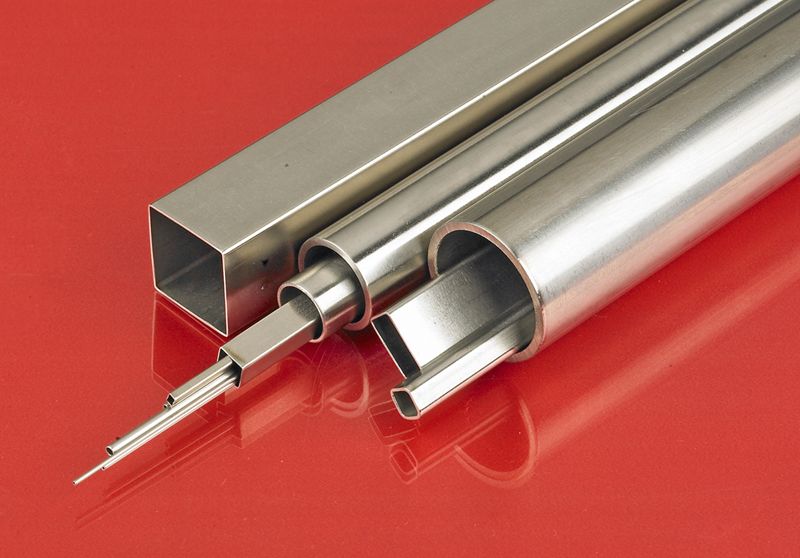

As a manufacturer of stainless steel and nickel alloy products, Best Stainless & Alloys offers stainless steel and nickel alloy bar, plate, and pipe. We are a leader in the distribution of pump shaft quality material. Other services that we offer are grinding, forging, castings, plasma cutting, heat treating and boring.

Cobalt and nickel alloys are manufactured here. Through our many service centers, we can supply you with nickel plate, nickel bar, forging stock, fittings, flanges, tubing and wire. When your application is in a severely corrosive or high-temperature atmosphere, we are the nickel supplier for you.

Since 1952, the Welding Warehouse has been manufacturing and distributing a variety of stainless steel products as well as titanium, aluminum, nickel, low alloy steel, magnesium, silver alloy and copper base alloy products. We also offer precision wire processing. In addition, we meet aerospace material specifications.

More Monel Suppliers

Properties and Types of Monel

At temperatures below zero, the single-phase, solid-solution binary alloy called Monel possesses exceptional mechanical characteristics. Monel comprises the following elements: 65-70% nickel, 20-29% copper, 5% manganese, and trace amounts of iron and other metals.

The composition of the various Monel alloys varies slightly:

Monel 400

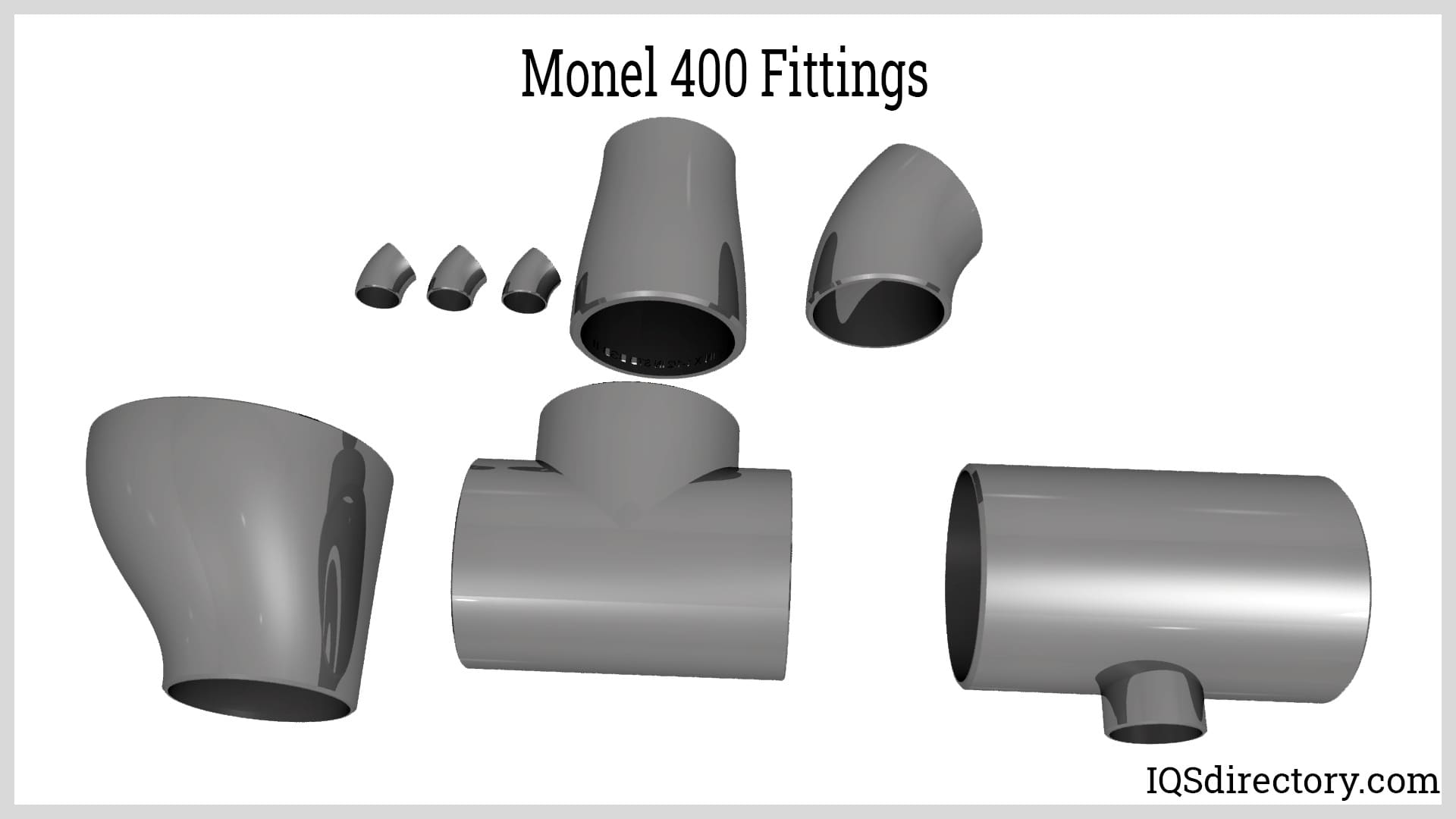

Monel 400 is made up of 63% nickel, 28-34% copper, 2.5% iron, 2% manganese, and trace amounts of silicon, carbon, and sulphur. It has good corrosion resistance to a variety of non-oxidized halogens as well as high heat and ohmic resistance.

Monel 401

Monel 401 is similar to Monel 400, with good brazing capabilities, a very low Curie temperature, and weak magnetic characteristics. The conventional methods for processing iron-based materials, including TIG and MIG procedures, are equally applicable to Monel 401. This alloy is frequently used for valve stems, pump shafts, impellers, conveyor scrapers, oil well drill rings, elastic components, valve matting, and other components.

Monel 404

Monel 404 contains tiny amounts of aluminum, manganese, silicon, carbon, and sulfur, as well as 52–57% nickel, 2% iron, and 45% copper. Monel 404 has superior all-around qualities, such as good corrosion resistance to hot concentrated alkali liquor and outstanding corrosion resistance to hydrofluoric acid and fluorine gas media. Additionally, Monel 404 is resistant to corrosion brought on by inorganic substances, the environment, water, seawater, and neutral solutions.

Benefits of Monel

The different chemical compositions of the Monel alloys make them suitable for different activities. For example, Monel K-500 is perfect for marine equipment applications due to its excellent resistance to corrosive seawater components. At the same time, Monel 404 is frequently utilized in the electronics industry due to its low permeability.

Additionally, Monel 405 resists seawater, high-temperature steam, salt, and caustic treatments. In a variety of mediums, it offers high corrosion resistance. It has good corrosion resistance together with comparatively moderate-to-high strength. Both hydrofluoric and hydrochloric acids won't harm it. At room temperature, it has a weak magnetic field.

Considerations for Buying Monel Alloys

Despite being flexible, Monel alloys can be challenging to machine because they rapidly stiffen in response to heat. Monel alloys must be twisted while machining at low feed rates and modest speeds. As a result, open die forging is often used to forge Monel alloys. Good strength, high malleability, a low coefficient of thermal expansion, and outstanding hygienic qualities are all attributes of Monel alloys.

Sectors That Use Monel Alloys

Marine

In the marine sector, Monel can be found in various fittings and fasteners, such as seawater valves, strainer baskets, trolling wire, etc. Other typical uses for Monel include valves and pumps, pump and propeller shafts, and electrical and electronic components. It can be found in a wide variety of small forms, like pipes, fittings, plates, strips, round bars, tubes, sheets, and wire.

Petroleum

Monel is used in storage tanks for gasoline, offshore drilling platforms, petroleum stills, and various processing machinery.

Music

Monel is found in ass guitar strings, tubas, French horns, trumpets, and other brass instruments.

Residential

Monel is used in interior decorations like decorative screens and doorknobs, as well as household equipment like kitchen sinks.

Industrial Production

Monel is used in producing equipment and parts, including boilers, chemical tanks, and diverse stock, including tubes, wire, sheets, and plates. Monel 405 is primarily utilized in the chemical, oil, and marine industries. Along with heat exchangers, alkylation facilities, brine heaters, steam generator tubing, pickling bat heating coils, and reboiling tubes for monoethanolamine, it can also be utilized in these applications.

Monel Finishing

Machinability: Monel is exceedingly difficult for the machine since it work-hardens during the process. Monel material can be machined using methods utilized on iron.

The preferred welding techniques for Monel are gas-arc welding, gas-metal-arc welding, metal-arc welding, and submerged-arc welding.

Forging: Monel can be forged; however, this must be done by strict guidelines. Monel alloy may be hot worked at temperatures between 1200 and 2150 °F (648 and 1176 °C). Therefore, it is necessary to choose the ideal temperature before beginning heated work.

Benefits of Monel

- Extreme corrosion resistance from both alkalis and acids

- Withstands alkalis

- Decent ductility (easy to shape and form)

- Simple to braze, solder, and weld

- Available in various shapes (sheets, plates, rods, bars, pipes, and tubes)

- High mechanical strength

- Appealing look and finishes

- Withstands fluctuating temperatures

Drawbacks of Monel

Although Monel offers several advantages, its shortcomings include:

- Poor machinability

- Exposure to pitting corrosion brought on by seawater

- May undergo galvanic corrosion

Choosing the Correct Monel® Supplier

To ensure the most positive outcome when purchasing Monel from a Monel supplier, it is important to compare several companies using our directory of Monel suppliers. Each Monel supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each Monel business website using our proprietary website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple Monel companies with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services