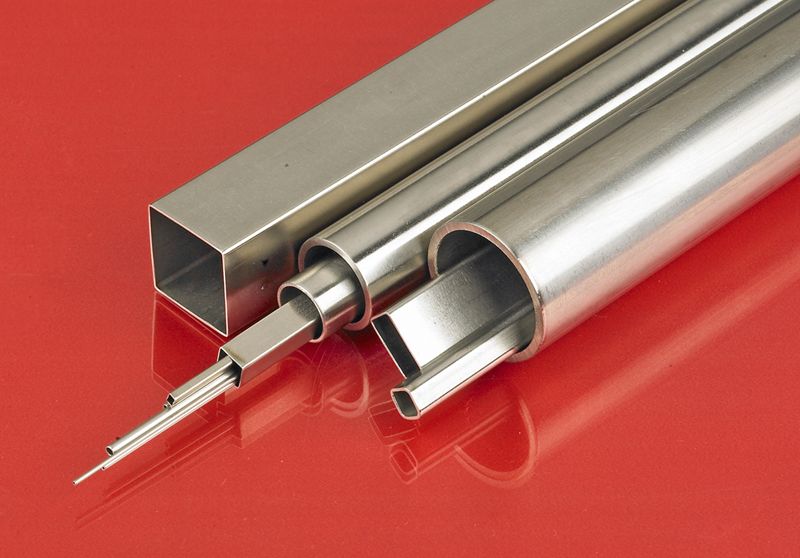

A nickel sheet is a thin, flat metal shape with uniform thickness. Nickel sheets are made from bullets or ingots of pure nickel. They are also made from nickel alloys. Nickel sheets are thicker than foil while thinner than nickel plates, varying between 0.006 inches and 0.250 inches. Read More…

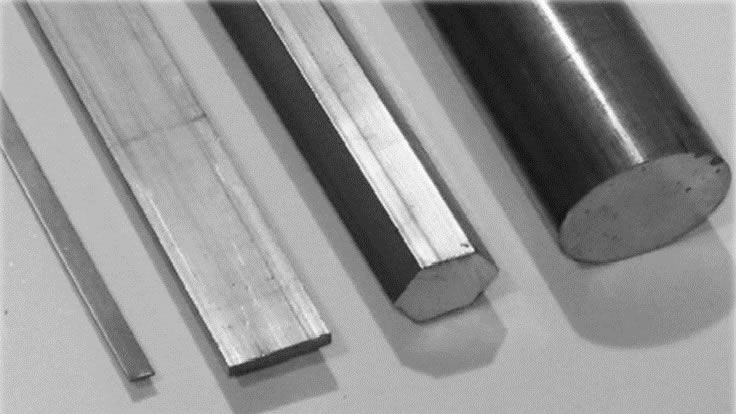

We will meet your nickel alloy needs with bar, strip or wire forms. Our ISO 9001-registered company would like to be your nickel supplier for nickel alloys — copper nickel, nickel copper, nickel chromium, nickel manganese, soft magnetic nickel iron. Round up to 15"; flat roll thin as .0002".

As a manufacturer of stainless steel and nickel alloy products, Best Stainless & Alloys offers stainless steel and nickel alloy bar, plate, and pipe. We are a leader in the distribution of pump shaft quality material. Other services that we offer are grinding, forging, castings, plasma cutting, heat treating and boring.

Cobalt and nickel alloys are manufactured here. Through our many service centers, we can supply you with nickel plate, nickel bar, forging stock, fittings, flanges, tubing and wire. When your application is in a severely corrosive or high-temperature atmosphere, we are the nickel supplier for you.

Since 1952, the Welding Warehouse has been manufacturing and distributing a variety of stainless steel products as well as titanium, aluminum, nickel, low alloy steel, magnesium, silver alloy and copper base alloy products. We also offer precision wire processing. In addition, we meet aerospace material specifications.

More Nickel Sheet Suppliers

What is a Nickel Sheet?

Nickel sheets are ideal stock forms because they have standardized measurements. This allows manufacturers to plan for efficient storage, transport, and secondary processing. Nickle is are ductile, malleable, and the sheets are very thin. This means it is easy to fabricate nickel sheets into specific shapes while maintaining the integrity of the material.

Nickel material is incredibly useful in sheet form, because it’s features include ferromagnetism, hardness, corrosion resistance, and electrical and heat conductivity. When buying nickel sheets, it is crucial to consider the specific alloy being usedbecause chemical, physical, and machining properties may vary.

The Process of Nickel Sheet Forming

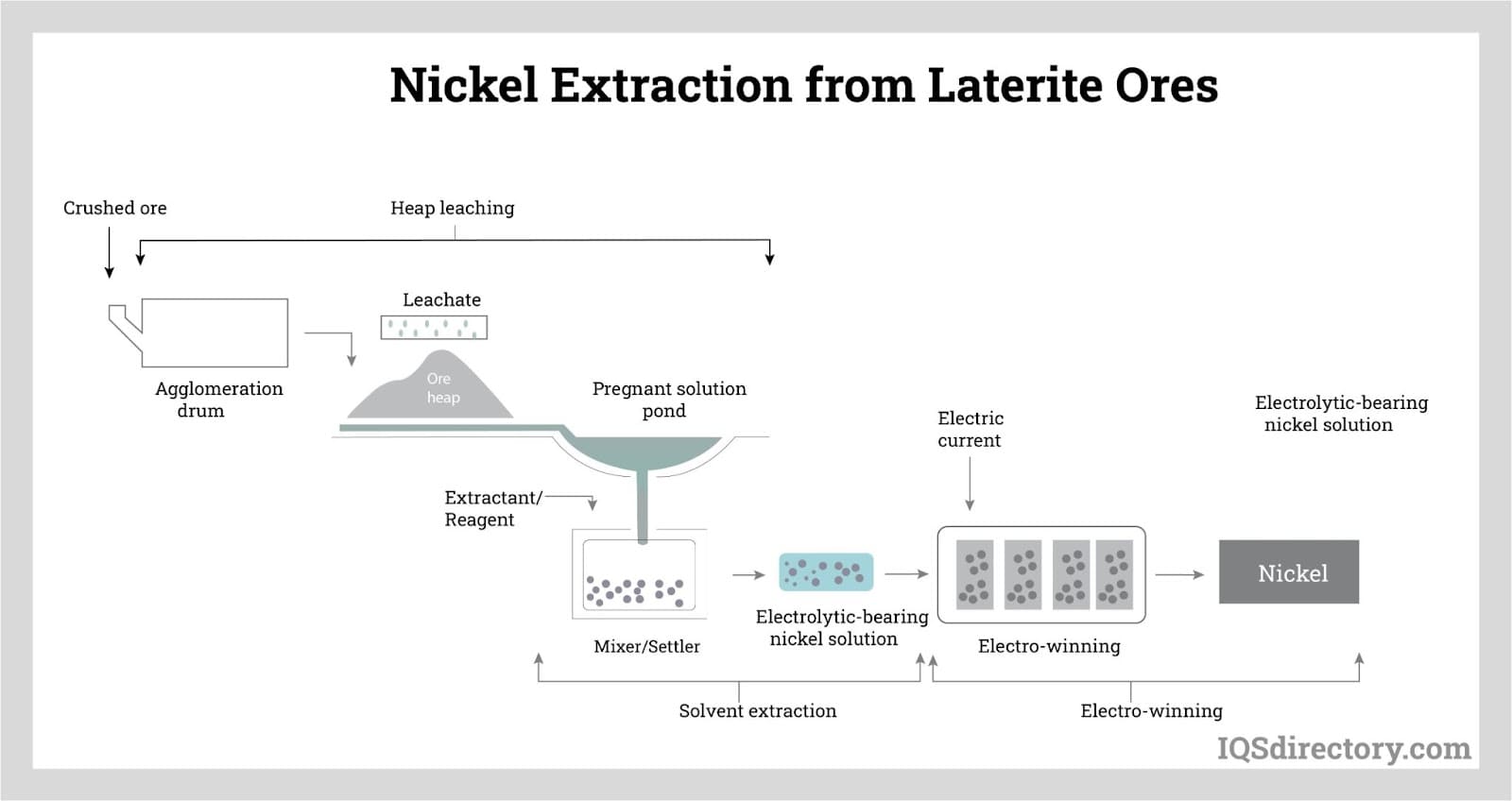

Before being made into sheets, nickel material is mined from the earth. Nickel is mined through hydrometallurgy or pyrometallurgical extraction. The nickel ore extracted is then refined through roasting and reduction processes until reaching the desired purity. Commercial grade nickel sheets contain 99.6% nickel. Some nickel alloys contain as little as 32.5% nickel.

Then the nickel (or the alloy) is formed into billets, ingots, bars, or other shapes that will formed into sheets. There are numerous processes used to produce nickel sheets. These include casting, extrusion, cold rolling, hot rolling, and drawing. The most common technique is hot or cold roll forming. In roll forming, the stock nickel is fed through a pair of rollers that compress the nickel metal into a thin sheet. The compressed nickel material may be heated or left at room temperature.

To achieve an accurate and consistent thickness, it may be necessary to use several rollers or many runs over the same rollers. To determine when this is necessary, Manufacturers should consider the nickel sheet’s intended purpose. Carefully evaluate the nickel sheet's thickness, gauge, length, breadth, and possible consequences of a secondary run.

After defining a purpose for your nickel sheet, the thin planes may undergo an assortment of operations. These include folding, punching, stamping, slitting, cutting, metal spinning, and other fabrication techniques that will produce a finished product.

Types of Nickel Sheets

The different types of nickel sheets include:

Hastelloy C-22 Sheets

Hastelloy C-22 sheets are made from a versatile nickel chromium molybdenum tungsten alloy. They are resistant to various industrial chemicals and easy to weld.

Hastelloy G-30 Sheets

Hastelloy G-30 sheets are made from a high chromium-nickel base alloy. They are also resistant to highly oxidizing acids and phosphoric acids.

Hastelloy B-3 Sheets

Hastelloy B-3 nickel sheets are used in chemical industry because they are resistant to sulphuric acid, hydrochloric acid, and phosphoric acid.

Hastelloy C-276 Sheets

Nickel sheets made from Hastelloy C-276 are also used in the chemical industry because they resist oxidizing agents and are easily fabricated.

Hastelloy X Sheets

Hastelloy X nickel sheets are used to make jet engine components for blades, tailpipes, afterburner sections, ducting, bellows, and honeycomb seals. They are strong and oxidation resistant up to 2200°F.

Haynes 242 Sheets

Haynes 242 nickel sheets are made from a nickel alloy that is perceptible to the age hardening process. Haynes 242 nickel sheets are oxidation resistant, have low thermal expansion, and ductile. Haynes 242 sheets are used in gas turbine engines and chemical processing plants.

Applications and uses of Nickel Sheets

- Nickel sheets are utilized in electronic wiring, sparking electrodes, and heat exchangers.

- Nickel sheets are used in battery components.

- In the oil, gas, and petrochemical industries, nickel sheets are used as an engineering material.

Benefits of Nickel Sheets

- Nickel sheets are corrosion resistant, versatile, and durable.

- Nickel sheets are flexible enough to be fabricated or welded into almost any shape.

- Nickel sheets are resistant to dry fluorine and other corrosive chemicals

Choosing the Correct Nickel Sheet Manufacturer

To ensure you have the most beneficial outcome when purchasing nickel sheets from a nickel sheet manufacturer, it is important to compare several companies using our directory of nickel sheet manufacturers. Each nickel sheet manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each nickel sheet business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to communicate with multiple nickel sheet companies with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services