Nickel Suppliers

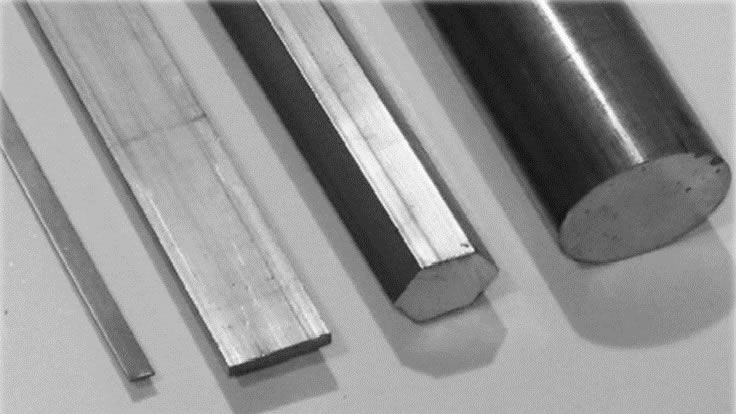

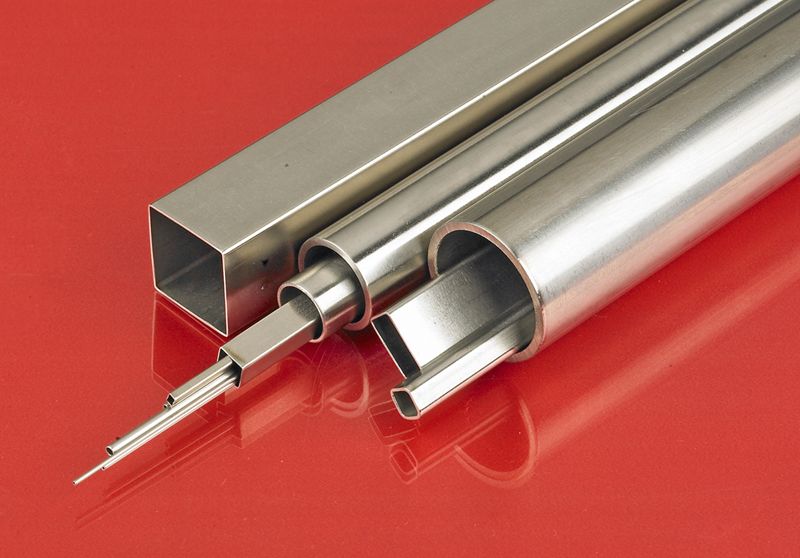

A silvery white metal, nickel suppliers provide nickel in a variety of forms such as sheet, rods, foil, bars, plates, wire and mesh. Since nickel must be mined from the earth, its original ore form is processed through extractive metallurgy. Read More…

Metal Technology specializes in fabricating products from high-temperature and corrosion-resistant metals. We can be contacted for your stainless steel, nickel, inconel, titanium, molybdenum, and zirconium needs and more. We have been in business for nearly 40 years providing standard and custom metal products and specialty metal tubing with extreme precision.

Since 1986 Magellan has been serving the global aerospace, oil & gas, power generation, petrochemical, bio-medical, pharmaceutical and other high tech manufacturing industries. Suppliers of nickel alloys, titanium, stainless steel and duplex alloys throughout the United States and in over 45 countries.

Sierra Alloys is a manufacturing service center specializing in titanium, PH grades of stainless, VAR aircraft alloy steels and nickel based alloys. Sierra's in-house forging and hot rolling equipment serves to meet and exceed the most stringent customer requirements. We have over 30 years experience.

TW Metals provides a variety of nickel products including nickel tubing, pipes, and bar rod wire. Our nickel based alloys offer high strength and heat resistance and can be used in contact with fluorine, hydrofluoric acid, hydrogen fluorine, or other derivatives. TW Metals stock seamless nickel tubing and pipes for both aerospace and commercial applications.

More Nickel Suppliers

The most common use of nickel after it has undergone extractive metallurgy is in the production of stainless steel. As a result, nickel suppliers typically supply to stainless steel and low alloy steel foundries and chemical companies. Electroplating is the second most common use for nickel behind stainless steel because nickel alloys are resistant to both rust and oxidation, and can be plated on many different surfaces.

Also able to perform electroless nickel plating, applications include electronic connectors, automobile trim, and bathroom fittings. In addition, most also supply nickel and nickel alloys in a broad range of forms, with the ability to forge nickel alloys into shapes including flat bars, rings or disks for the aerospace, automotive, medical, food service and many other industries with applications including guitar string, magnets, coinage, rechargeable batteries and more.

Nickel suppliers typically provide a broad spectrum of nickel alloys. Often alloyed with metals including with copper, chromium, lead, silver, cobalt, gold and aluminum, the amount of nickel in these alloys can vary from 32.5% to 99.5%. However, there are some alloys that are more common than others, and will be more regularly supplied on a stock basis rather than a specialty order.

Defined as metal alloys in which nickel is the most prominent element, nickel alloys are typically categorized in four main group: low-expansion alloys, electrical resistance alloys, soft magnetic alloys, and shape memory alloys. Electrical resistance alloys can be further broken down into two sub-categories: resistance alloys and heating alloys.

Low expansion alloys are nickel alloys that are specifically engineered to have low thermal expansion and include Invar, Kovar, Inconel 718, nickel-cobalt alloys and nickel alloy 625. Electric resistance alloys are nickel alloys with a high nickel content and include alloys such as Nichrome and copper-nickel alloys.

Soft magnetic alloys are nickel alloys with high magnetic permeability and low saturation induction including iron-nickel alloys. Shape memory alloys are nickel alloys that are capable of returning to their prior shape upon undergoing the appropriate heating schedule such as copper-aluminum-nickel alloys and nickel-titanium alloys.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services